SILVER BRIGHT

PRECISION ERW STEEL TUBES in Carbon Steel and Stainless Steel

SILVER BRIGHT

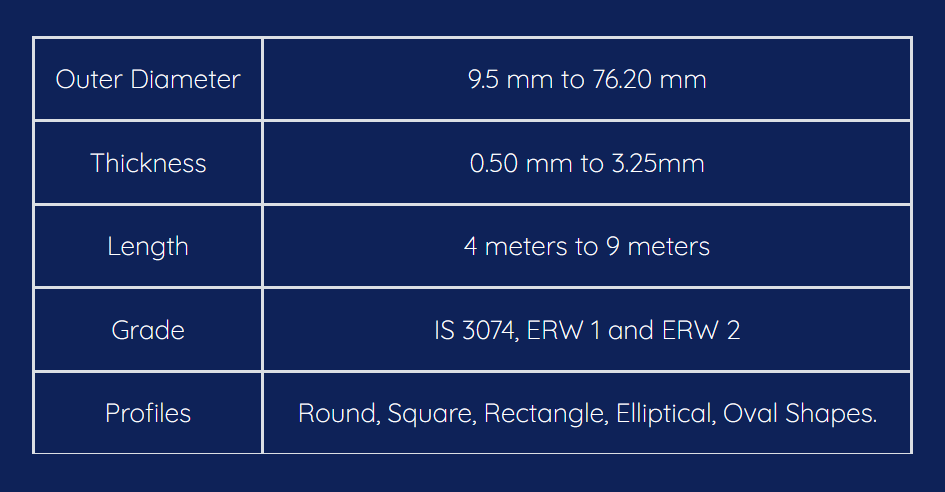

Product Details

Tubes are manufactured from steel strips, slit from Cold Rolled Low Carbon Steel coils. The strip passes through a series of drive forming and fin rolls and takes the required circular shape and is welded continuously by passage of an electric current of high frequency i.e. 4,50,000 cycles/second across the abutting edges. The tubes thus formed and welded pass through the sizing sections where dimensional deviations if any are corrected before the tubes are cut into required length by automatic cutting machines. The tubes are then end deburred. Thereafter protective surface finishing operations such as varnishing is done as per specific requirement.

Applications

- In automobile industry for chassis, handle bars, seat frames, stands, front and rear guards, steering columns, gear shaft, shock absorbers, swing arm, etc.

- In boilar, air pre-heater and electro static precipitators.

- In furniture industry for manufacturing chairs, tables, sofas and hospital equipments.

- In construction industries for scaffolding & structural purposes

- In pipe lines for natural gas, LPG and other non-toxic gases

- In power projects & fire fighting system.

- In cold storage industry.

Quality Control

- Raw material of the right grade is ordered as per customer requirement.

- The slit coils are inspected and inward report is generated.

- Online non-destructive testing.

- Our QA team tests for tensile, yield, flattening, hardness and elongation in our in-house laboratory.

- This is carried out in real time and necessary corrective action (if any) is taken.

- Every tube is individually inspected and dipped in high grade oil to prevent rusting. Batches are formed. Each batch has a stacking report, consisting of mechanical, physical and chemical properties.

- Pre-dispatch inspection completes the quality loop.