Aluminium Extruded Profiles

About Aluminium Extruded Profiles

Silver Bright was established in 1974 and manufactures bright steel bars from carbon steel and ERW/CEW Precision Steel tubes.In fact, we setup the first facility to manufacture precision drawn bright steel bars in Pune, way back in 1974. The last 30 years has seen us growing from strength to strength. The ERW/CEW Precision Steel tube plant opened in 2006 and is again the first and only facility of its kind in the Pimpri-Chinchwad industrial belt.The company has grown to become a leading supplier of bright bars to over 300 customers and OEM manufacturers. We employ nearly 100 associates. With our core values like business integrity and high ethical standards, quality manufacturing, and exceptional customer service we have successfully penetrated the market and established a benchmark that others vie for.One of our greatest strength is the quality of our people. We support and encourage, stimulate and challenge. Our people are our culture.

ALUMINIUM EXTRUSION FACILITY

We have fully PLC control extrusion press of 1000 MT which is capable of producing a variety of profile’s as per customers requirements & Our current annual production capacity is 2400 Tons.

We have our own foundry with Hot Top Log Casting Furnace system to make billets covering a wide range of alloys ranging from series 1XXX To 7XXX such as 6063, 6061, 6082, 6101, 6005, 6066, 1050, 1070, 3003, 63400, etc in Temper 0, F, T4, T5, T6. Complete metal treatment procedures as grain refining, filtration, degassing & homogenising are carried out.

We have Hot log shear electromagnetic log heater, Die Oven & Ageing Ovens for artificial aging of material. Inhouse facility for design & die correction room for the complex Profiles.

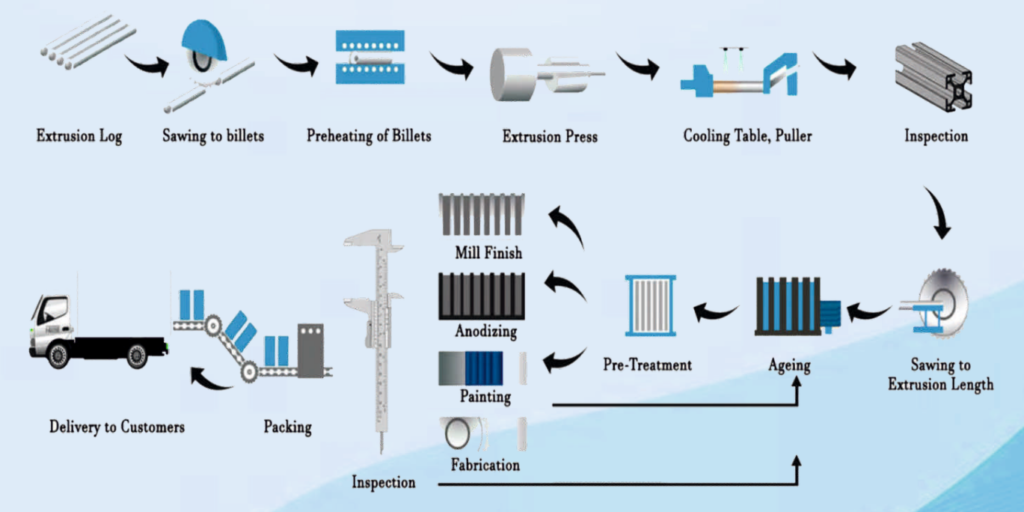

EXTRUSION PROCESS

PRODUCT APPLICATION

Aluminium extrusion has many excellent properties such as a good electrical conductor, low weight, thermal conductivity, corrosion resistance, formability, machinability, recyclable, design possibilities, therefore offering high value in numerous applications.

- AUTOMOTIVE & ROAD TRANSPORT

- RENEWABLE ENERGY

- TRANSMISSION & DISTRIBUTION

- LUGGAGES

- ELECTRICAL & ELECTRONICS

- ARCHITECTURAL PRODUCTS

- TEXTILE MACHINES

- DEFENCE

- CONSTRUCTION INDUSTRIES

- MEDICAL EQUIPMENTS

- ADVERTISING

- CUSTOM MADE & MANY MORE

OUR QUALITY CONTROL

For Aluminium profiles Chemical & Mechanical properties play a major role in end applications. The Chemical composition of every cast in our foundry is checked on a Spectrometer. Properties such as mechanical strength & hardness are tested on a tensile testing machines & hardness testing equipment.

ANODIZING & POWDER COATING

SILVER BRIGHT EXTRUSION PVT. LTD. Offer Anodizing & Powder coating for surface finish on request.

- Glossy /Matt Finish.

- Upto 25 Micron Thickness.

- Upto 6 Meter Length.

- RAL Colours

- 60 – 80 Microns Thickness.

- Upto 6 Meter Lengths.

MACHINED COMPONENTS & PACKAGING

SILVER BRIGHT EXTRUSION PVT. LTD. Can provide customized operations on aluminium sections to save processing time & cost as well as to shorten lead times, on request.

During transportation to keep section & there surface safe, we can provide interleaving with paper, polythene, stretch film, bubble sheet & Card Board as required. Wooden box, pallets can be used transport distance & section sensitivity demands. Bundles are made to facilitate manual loading /unloading. Also have inhouse 60m weighing scale to dispatch the material promptly.

- Milling.

- Drilling

- Punching

- Deburring

- Bending

- Angular Cutting

- Upto 6 Meter Lengths.